I struggled to get the pulley off of the spindle after a few attempt and decided to get a new one from Amazon. After that arrived I had everything I needed to start the assembly process.

Spindle was installed first, followed by a quick sharpening of the blades while they were easily accessible. I kept the rope on the right spindle that I used to get the blade off to hold the opposite site of the blade this time to reinstall it. It would have been too difficult to try to hold the blade and tighten with the tire iron.

I didn’t get a picture of it but I installed the new pulley on the spindle and tried to fit the first belt back on. No matter what I did it would not tighten all the way and after double checking the routing in parts diagrams I finally realized that the pulley I bought was slight smaller in diameter than what I needed, causing the belt to be extra loose.

So I switched gears and decided to try extra hard to get that pulley off the spindle. I made a little 2×4 blocking and screwed it all together to hold the spindle and pulley off the ground. I used a torch for a good 5 minutes to heat it up, grabbed a large bolt and larger hammer and starting hitting it up finally it released and started to work itself free from the spindle.

Leaving that to cool down I went to the mower and jacked up the rear and set it on some concrete blocks to access the underneath. I removed the two brackets that hold the mower clutch pulley from spinning around once engaged to give me enough room to work the new belt up on the drive pulley attached to the bottom of the motor. I needed to start installing the belt over a bracket toward the front of the mower first, then hooked it around the pulley and reinstalled the two brackets.

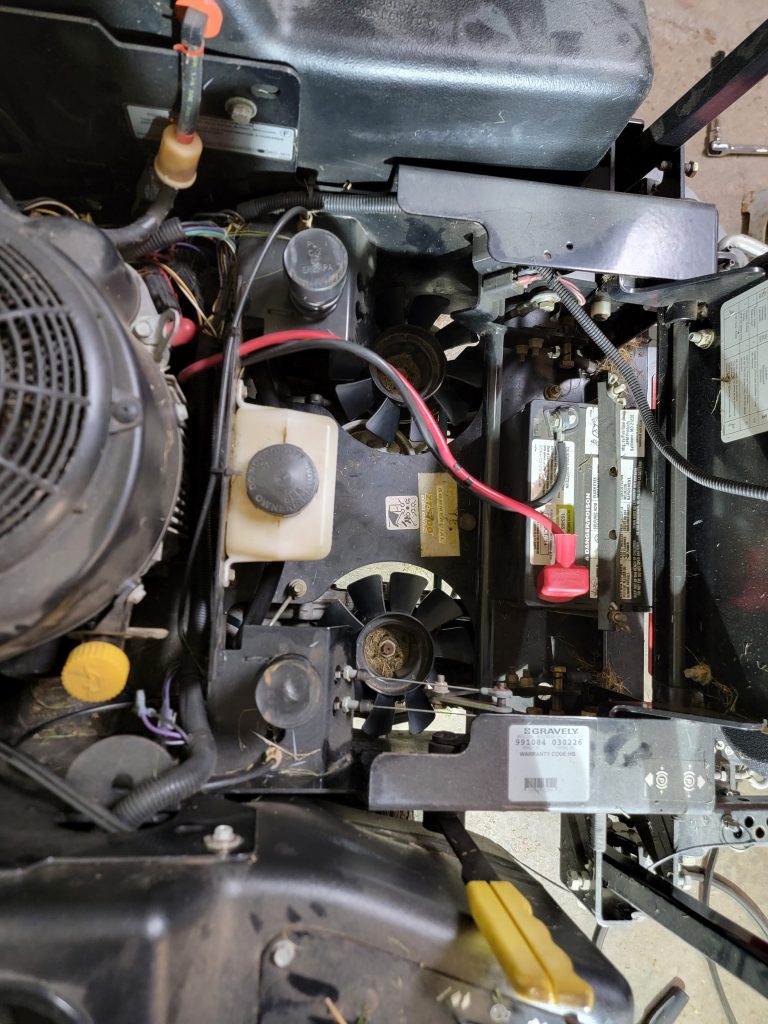

Next I was able to work the pulley around the two motor drives, around the fans and back down. The last pulley to get the belt around was the left side of the mower, it was very tight and I was struggling to get it around. After nearly giving up and taking off the tensioner bracket I gave the key a kick to start the mower and it was just enough to spin the belts to seat it! Somehow I got lucky that I installed it in the correct direction to make that work for me. I was trying to install the belt on the pulley clockwise and the mower drives it clockwise.

I took the mower off the block and lowered back to the floor. Pushing the deck over and under it I started installing that back on. The two large brackets first, then I put a 2×4 in the deck height adjuster to kept it lowered and take the spring tension off. Replaced the four bolts in the corners to the deck height adjuster and it was back installed.

Finally, I installed the double pulley on the spindle since it was cooled down and routed the last mower deck belt.