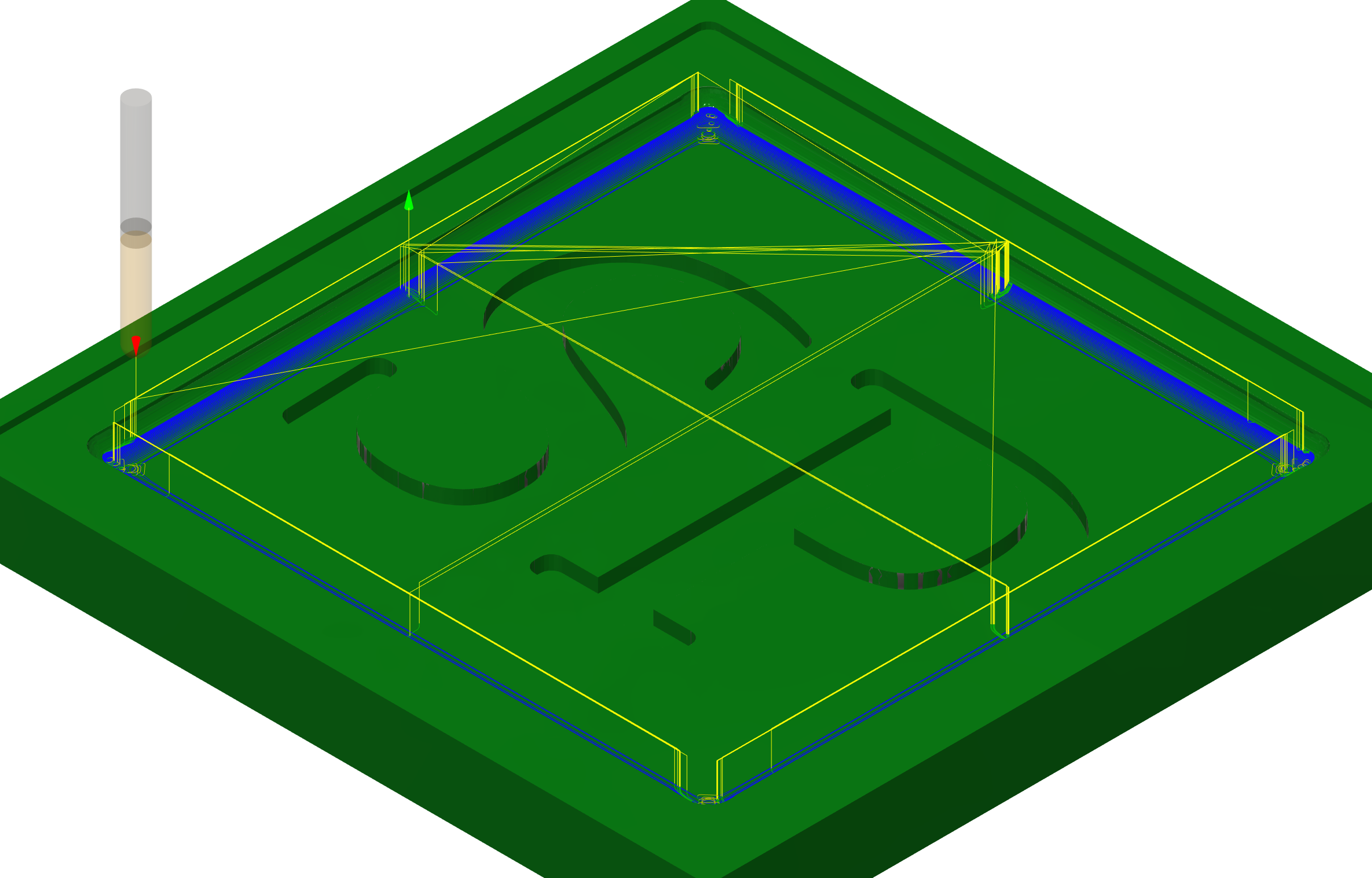

Creating a wall sign for grandma to hang-up gives me another opportunity to use epoxy to fill in engravings in wood. The design was created in Fusion 360:

The toolpaths were created, two for engraving (90 degree V-bit) and the last for the cutout (1/4″ upcut):

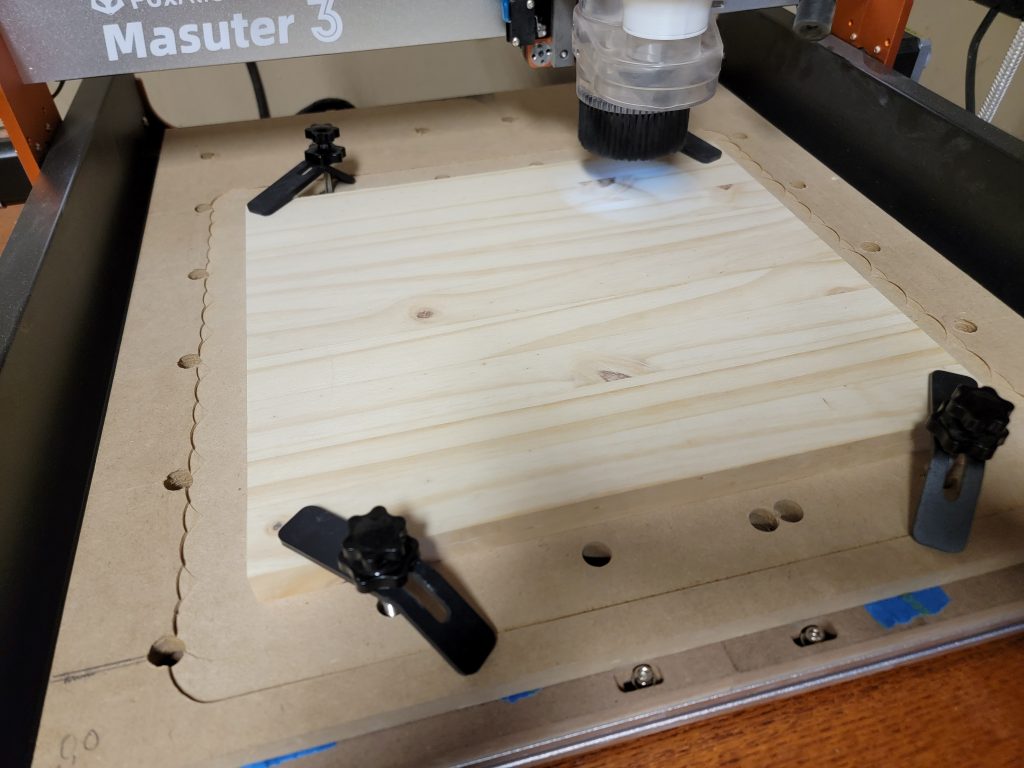

Fired up the FoxAlien CNC and it was off to engraving, total time was about 25 minutes.

The cutout toolpath took approximately 30 minutes:

Once the CNC was completed I used the jigsaw to remove it from the stock and the router with a round over bit to clean up the edges. Learning from the last attempt, I liberally applied polyurethan to hopefully seal the wood and prevent it from wicking up the epoxy like it did on the first try

Applied another two coats and let it sit overnight before starting the epoxy pours.

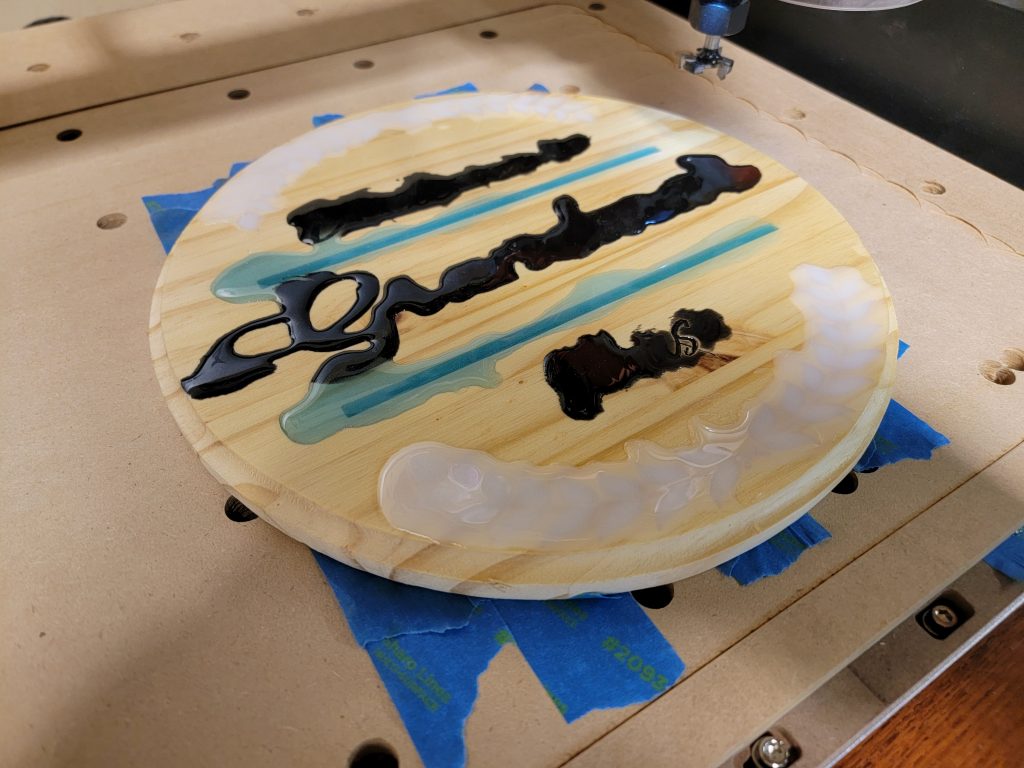

I decided to go with three colors: white, blue and black. I mixed up each in a separate cup pouring .6oz of epoxy and hardener in each cup, followed by 3 drops of coloring.

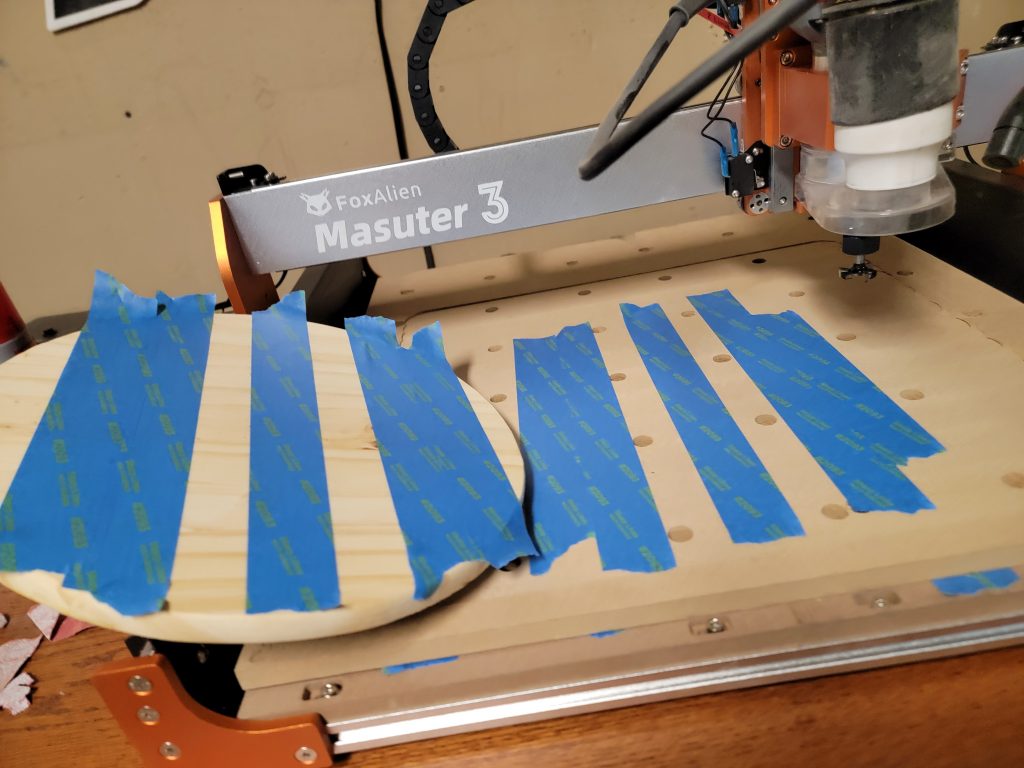

After 24 hours of curing I brought it back out to the garage and used the CNC to surface it. I stuck with the piece to the CNC with the usual painters tape and instant glue.

Leaving the piece stuck to the CNC I sanded the face up to 400 grit in preparation for applying Bush Oil. Prying it off was easy and I brought it over to another bench for finish.

Final shot:

Using polyurethane prior to pouring epoxy into the engraving worked much better than without it. The deeper cuts were nice and crisp and did not wick the epoxy into the wood grain. I think the shallower engravings didn’t get enough polyurethane because of the spray angle(?), you can see this on the “H” in house.